Release time:2022-01-10

Injection moldingIt is a field with high technical content. In addition to years of experience accumulation, we should also have a heart that is good at discovery and be familiar with the whole injection molding process. To correctly learn all aspects of injection molding processing requires a lot of repeated experiments, constant trial and error and summary. However, considering that we have many years of innovative experience in the field of injection molding, it can help all those who want to engage in injection molding processing to avoid detours. Instead of spending time meditating. If you plan to produce injection molded parts, the following are four main design options for reference:

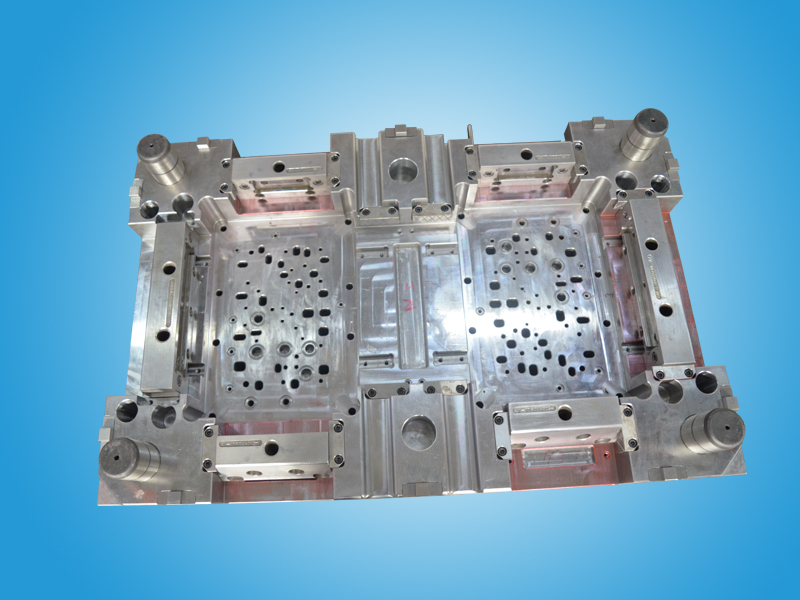

Mold design parameters:The design of injection mold is a very important part of injection molding project, which is also time-consuming, because it requires a lot of thought. It is very important for the success of injection molding enterprises to do things well at the first time. In order to obtain the best injection products, there are many design parameters to be considered, among which the draft and cavity bending are very important.

More complex molds have many complex cavities, and plastic must pass through these cavities to fill all the cavities. These bending, especially when the bending is very intense, will lead to the in mold stress at the atomic structure level and the in mold stress of parts with different cooling methods from the outside to the inside. Designing the mold into smoother and softer turns will avoid sudden changes in flow direction and prevent these stresses from accumulating in the parts.

Drafting (or more accurately, stretching angle) is the thinning of a part, which aims to make it easier to push out the part when the mold is opened. Sometimes drafts are incompatible with part design, whether from an aesthetic or functional point of view, but a smaller draft is always better than no draft. The required draft also varies depending on the surface finish of the tool or the texture requirements of the part. Smoother tools require fewer drafts than normal tools.

Part design parameters:The design requirements of injection molded parts are the combination of manufacturability, practicality and aesthetics. Compromise between factors such as repeatability, cost, strength, function and aesthetics. A balance will be sought to ensure that all these factors are not below the minimum requirements. From the perspective of injection molding, the uniformity of part wall thickness and design parameters such as part wall thickness itself are key factors. Uniform part thickness will ensure that warpage, deformation or cracks caused by uneven wall thickness caused by part cooling at different cooling rates are minimized. The consideration of part thickness is mainly determined by cost, part strength and production speed. Thicker parts cost more because they consume more plastic, while thinner parts cool faster and can be discharged earlier, saving critical time in the production process. However, despite the additional cost, thicker parts are usually stronger.

Gate design and positioning:In injection molding, there are generally two kinds of gates: manual edge adjusting gate and automatic edge adjusting gate. As the name suggests, each type of manual or automatic disassembly of parts from the mold has a specific reason for use. If the ram is too heavy to use the automatic integrated de gate cutter, the ram can be cut manually. Automatic gate trimming is used to reduce the downtime of manual gate disassembly, so as to achieve uniform production speed.

The gate position is usually located near the thicker part, from which the melt flows to the thinner area of the mold. This ensures the minimization of part defects, such as dents, gaps, and inadequate part packaging. In some cases, it may be necessary to include a secondary gate to ensure the correct filling of the cavity. Reduce the wall thickness to make it thickest at the gate, and then make the cavity thinner downward, which will ensure good flow.

Forming conditions and parameters:These variables are easy to adjust, such as mold and melt temperature, cooling time, injection pressure, injection speed, holding pressure and time, which will affect the effect of finished products. All these factors have an impact on this part. Sometimes these impacts are negative and need to be minimized. However, adjusting a variable to limit a specific defect may make the component vulnerable to another defect; Therefore, a balanced behavior is followed by the right trade-off to meet the necessary requirements and partially meet its expected functional satisfaction.